How a Lean Layout helps during the COVID-19 Crisis

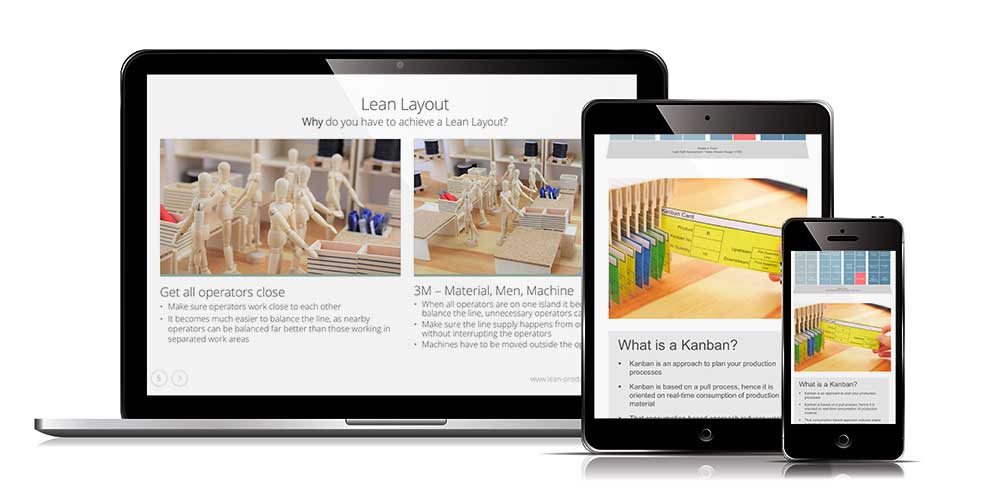

The current COVID-19 crisis forces many companies to utilise the flexibility of their shop floor process. A few years ago, we prepared a video in which we show and teach on how to increase this shop floor flexibility.

As demand and volume drops, it is highly important to understand this importance of shop floor dynamics.

We recommend to watch the video to its end to see the link of volume to a lean layout. A drop of volume results in a drop of required capacity in material, man and machine. As most modern assembly lines and machinery parks are based on a peak demand at 100%, the COVID-19 crisis demand drop to almost a minimum at many sites.

A Lean Layout allows lean factories to react to this drop in demand without any additional costs or effort. Though the Lean Layout principle is not the only aspect supporting a factory to react to this situation, it is one of the key factory.

To download three hours of more training videos about all kind of lean tools, check out the entire Lean Toolbox download below:

A Workshop Training Kit