Play the Lean Factory Game

– The Fun Lean Training Game.

Turn your Lean training into a fun, hands-on experience that engages your entire team

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

USED BY LEADING COMPANIES FROM ALL AROUND THE GLOBE

What is the Lean Factory Game?

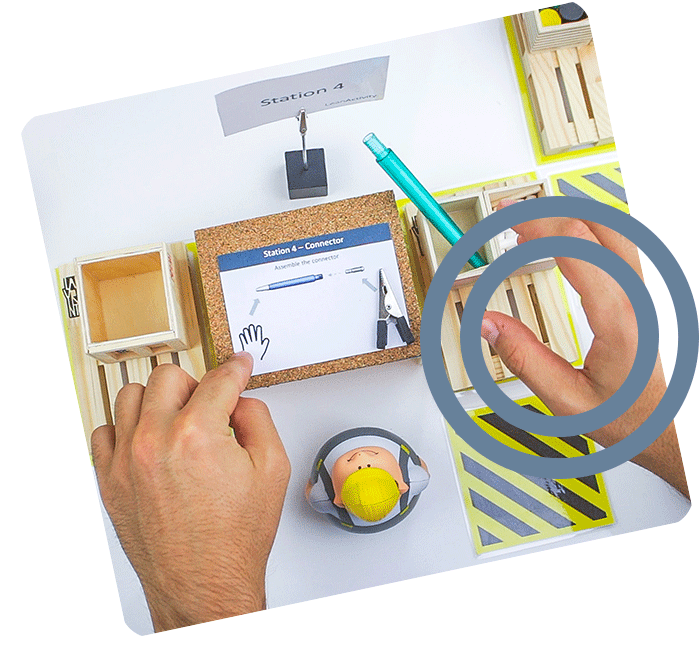

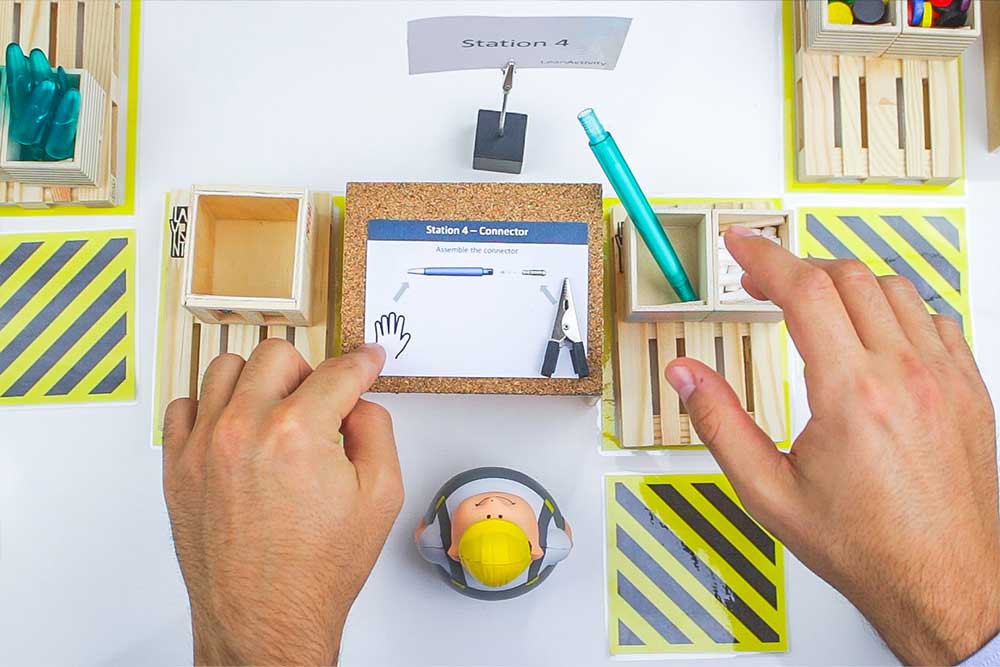

The Lean Game is an interactive Lean simulation designed for team trainings and workshops. During a 4-hour session with up to 12 participants, you take on the role of the Lean Trainer.

#lean #training #game

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

Why Traditional Lean Trainings Often Fall Short.

Many Lean trainings are too theoretical and, as a result, fail to engage participants. Consequently, teams often forget key tools and methods shortly after the session.

Fortunately, we understand the Lean training problem – and therefore we solved it with gamified, hands-on experiences that truly stick.

Key facts about the

LeanActivity Factory Game.

How does the Lean Game work?

Excited to learn more about the game? Then this is important to know:

Request the Management Briefing Pack and see the Lean Game in all Detail.

What Lean Tools are part of the Lean Game?

Download the Lean Game Management Briefing - and experience the Game yourself.

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

Participants learn the effects of waste reduction and process improvement in a playful, hands-on way.

Take the chance to get your Team committed towards Lean principles and run your real workshop after the training!

Request the Management Briefing Pack and see the Lean Game in all Detail.

Join the Free Daily Webinar

– Reserve Your Spot Now.

From Setup to Wrap-Up: Watch One Day with the Lean Game.

The Story behind the Lean Game.

LeanActivity was founded in 2016 by the two Lean Coaches, Martin Schneider and Sergen Retzep.

Since then, their award-winning simulation game has been distributed and supported by universities, furthermore developed in collaboration with consultancies, and tested with manufacturers all around the globe.

If you want to experience it yourself, catch us at any upcoming live event, or reach out to us for the latest dates.

Most frequently asked Questions

Got questions? We’ve got answers – straight from the shop floor.

The game is designed for 6 to 16 players. It includes 8 active roles, such as assembly worker or logistics operator.

Additionally, extra participants can take on the role of Gemba observers, who closely watch the game, provide input and actively participate in discussions.

For groups larger than 16, we recommend using two sets and dividing the group into two teams in the same room. This way, it creates an exciting competition and keeps everyone engaged.

For example, top management teams often prefer a condensed 60-minute version, focusing only on selected topics such as SMED or Lean Logistics. Meanwhile, consulting firms sometimes extend the program over several days, combining the game with their own training content.

In this way, the game becomes part of a flexible, customized learning experience.

The game is ideal for companies that actively work with Lean Management and want to bring Lean thinking to life on the shop floor. As a result, it works as an “eye-opener,” inspiring teams to embrace Lean initiatives with real enthusiasm.

Moreover, beyond industry, the game is also used by universities, business schools, and consulting firms, making it a versatile training tool across different contexts.

We ship the LeanActivity Factory Game worldwide. To ensure smooth delivery, our experienced logistics partners handle all customs documentation and shipping requirements.

Delivery time varies from just a few days within Europe to up to 4 weeks depending on the destination country. Furthermore, all shipments are dispatched from Germany within the EU, ensuring reliable and secure transport.

The Factory Game consists of 10 game rounds, each focusing on a key Lean Management principle:

- Waste elimination, work instructions & standardization

- Visualization

- 5S workplace organization

- Lean layouts, material flow & improvements

- SMED (quick changeovers)

- Small batch sizes & material containers

- Supermarket & milk run logistics

- Pull principle

- Design for manufacturing

- Kanban & Heijunka (leveling)

Through this step-by-step approach, Lean becomes both practical and tangible for all participants, allowing them to experience real improvements in a hands-on environment.

The game comes in a durable transport trolley, which contains all necessary materials: a factory warehouse, supermarket, playing figures, materials, route train, all cards, and documents.

In addition, buyers receive access to our online platform, which includes training videos, supporting materials, and the Train-the-Trainer course. This way, everything is included to make the game fully ready-to-play from day one.

Yes, a comprehensive Train-the-Trainer program is included, which guides facilitators step by step through each round.

Moreover, the Factory Game is intuitive and easy to run, supported by detailed online resources.

In addition, trainers have access to direct video support from the LeanActivity team, ensuring smooth implementation.

As a result, even newcomers can confidently deliver the game with excellent results.

The online platform is the central facilitator’s tool. It provides videos, detailed instructions, and explanations of all Lean methods used in the game.

Furthermore, it actively guides the trainer through each round and serves as a digital co-trainer, thereby ensuring consistent quality and ease of facilitation.

As a result, the learning experience becomes highly structured and reliable.

Yes, the Factory Game is flexible. Trainers can, for example, choose to focus on selected rounds depending on the target audience, whether it’s production teams, logistics staff, or executive management.

As a result, this adaptability allows organizations to tailor the learning journey to their own Lean transformation needs.

Absolutely. Many companies use the game in executive workshops as a strategic tool. For example, top managers benefit from a condensed version that highlights Lean principles in action, thereby providing a powerful eye-opening experience without requiring a full day of play.

Yes. Consulting firms worldwide use the Factory Game to enrich their Lean programs. For instance, it allows them to combine their own content with the game, thereby stretching sessions over multiple days.

As a result, this creates a highly interactive and memorable learning experience for their clients.

Unlike traditional training methods, the Factory Game combines realistic production scenarios, hands-on problem solving, and immediate feedback loops.

As a result, it creates a powerful link between theory and practice, thereby making Lean Management not only easier to understand but also far more engaging and motivating for participants.

The Factory Game is not limited to production employees. In fact, it is highly valuable for all departments, including Sales, HR, Finance, and Administration.

Lean is not only about improving shop floor processes – it’s also about creating a holistic culture of efficiency andproblem-solving across the organization.

When non-production staff participate, they gain deeper insight into how value is created in the factory and how their own roles connect to it. As a result, this often leads to cross-functional understanding, better collaboration, and stronger commitment to Lean initiatives throughout the company.

No, both games are completely independent and come with their own unique materials and setups.

Specifically, the Factory Game focuses on production processes, while the Office Game addresses Lean in administrative areas.

However, they can be combined for extended Lean training programs, yet each works perfectly as a standalone experience.

Ready to start your Lean Gamification Journey?

Get your Lean Game Management Briefing and find out

Lean Game Management Briefing

A Demo Insight into the LeanActivity Factory Game

FREE

Experience the LeanActivity Factory Game and explore how the game works for you. Incl. ROI & Case Studies

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Start now

Lean Factory Game

Physical Product

(worldwide shipping)

3298€

Play Lean on the shopfloor and learn Lean methods through hands-on, simulations

Start now