Play the Lean Factory Game

– The Fun Lean Training Game.

Turn your Lean training into a fun, hands-on experience that engages your entire team

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

USED BY LEADING COMPANIES FROM ALL AROUND THE GLOBE

What is the Lean Factory Game?

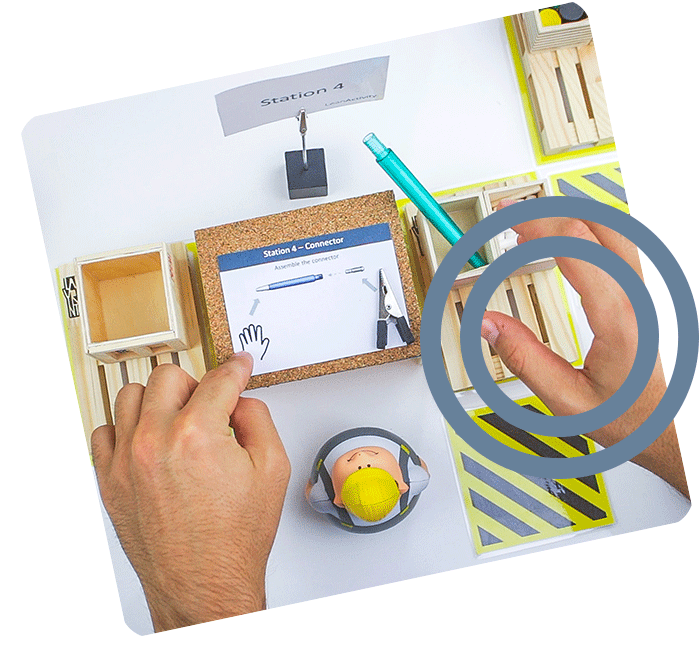

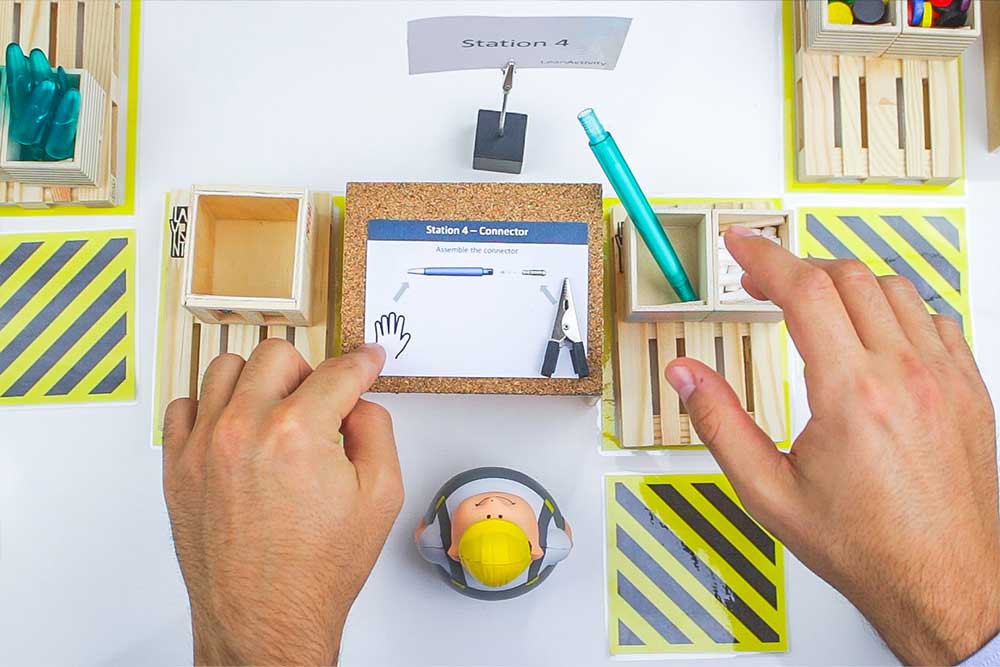

The Lean Game is an interactive Lean simulation designed for team trainings and workshops. During a 4-hour session with up to 12 participants, you take on the role of the Lean Trainer.

#lean #training #game

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

Why Traditional Lean Trainings Often Fall Short.

Many Lean trainings are too theoretical and, as a result, fail to engage participants. Consequently, teams often forget key tools and methods shortly after the session.

Fortunately, we understand the Lean training problem – and therefore we solved it with gamified, hands-on experiences that truly stick.

Key facts about the

LeanActivity Factory Game.

How does the Lean Game work?

Excited to learn more about the game? Then this is important to know:

Request the Management Briefing Pack and see the Lean Game in all Detail.

Download the Lean Game Management Briefing - and experience the Game yourself.

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

Participants learn the effects of waste reduction and process improvement in a playful, hands-on way.

Take the chance to get your Team committed towards Lean principles and run your real workshop after the training!

Request the Management Briefing Pack and see the Lean Game in all Detail.

Kick off your Lean Transformation, order your FREE Lean Game Management Briefing here.

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Download the Lean Game Case Study Pack – See Real Results.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

*containing KPIs and Return on Invest (ROI), Real Case Studies from Automotive Industry and more

Ready to start your Lean Gamification Journey?

Get your Lean Game Management Briefing and find out

Lean Game Management Briefing

A Demo Insight into the LeanActivity Factory Game

FREE

Experience the LeanActivity Factory Game and explore how the game works for you. Incl. ROI & Case Studies

Excited to Buy the Lean Game? Download the free Case Study Pack first.

incl. Case Studies, Video Insights, ROI Cases and real Shopfloor Results.

Start now

Lean Factory Game

Physical Product

(worldwide shipping)

3298€

Play Lean on the shopfloor and learn Lean methods through hands-on, simulations

Start now